The Uses And Type of Milling Machines

Milling machines come in more than a few types with a spectrum of features based on particular specifications. Some of the most generally utilized machines are of the following: column, C- frame, bed-type, tracer-controlled, turret, horizontal, and planner-style.

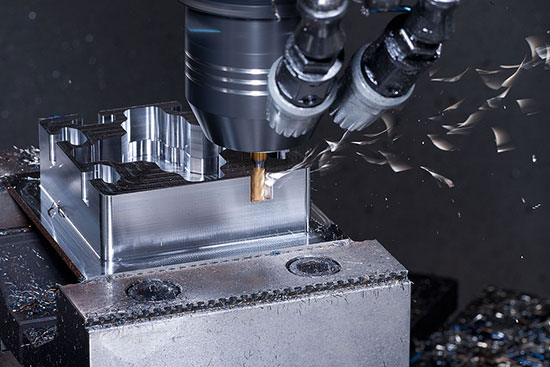

A milling machine is a device in the metal industry that has several functions. Every machine has a cutter that functions at a variety of range speeds, so you can structure the necessary shape. With its adjustable speed option, every milling machine can be regulated for a greater precise cut. The machine is able to handle a list of tasks such as threading, carving, cutting, drilling and milling.

There are numerous kinds of milling machines, each with various features based on standard specifications. Manufacturers often identify the separate machines according to the variety of control, count of axis present, position of the spindle, measurement of the tool, its duty, and origin of power. While there are countless types of milling machines currently accessible, they primarily serve similar functions, but utilize separate terminologies. Beneath is a list of types of milling machines.

Column

This is the most common milling machine that has five primary components. They are the work table, over arm, head, saddle, and knee. Considered as the easiest machine type, its cutting system is vertically placed to permit the drilling of metals. This is normally utilized when constructing auto components.

Turret

The turret is also recognized as the Bridgeport- type and can be manipulated each time you prefer, making this machine extremely functional. Its adaptability makes it extra helpful due to the fact that a range of products can be made in conjunction with automobile parts.

C-Frame

Because it is more stable than a turret, this kind of machine is better known in industrial locations. It possesses a hydraulic motor, which makes it very powerful.

Horizontal

This machine runs aligned to the ground. The table, where the object to be labored on, is positioned and rotates sideways as the slicing mechanism moves up and down.

Bed-Type

This worktable is positioned on the bed itself, rather than of being placed on top. Its regular position, the knee section of the machine, is left out to permit movement in a longitudinal route.

Planner-Style

This machine is basically the equivalent of the bed-type. However, the planner style comes along with cutters and heads that permit a wider range of milling actions.

Tracer-Controlled

This kind of machine has the capacity to reproduce components based totally on a master model. A majority of the industrial sectors, especially the automobile industry, select this type of machine because it allows for easier manufacturing and specialization of machine components. With the extensive classifications of milling machines, you may want to select the one you require based on how you plan to utilize it. However, if you find it tough to decide, do not hesitate to find the assistance of a professional who can assist you with your choosing the one that will provide you the most benefits.

To upgrade milling or routing machines, MegaStir is now offering their friction stir welding instrumented tool holder which offers high-speed process sampling of customer-selected avenues for either z-axis load, tool temperature, or tool torque for total control for the friction stir welding process. The system may also be established with analog outputs for integrated device control utilizing force or temperature guidance systems.

The CNC (computer numerical control) machine or machining center is an extremely precise form of milling. This machine is set up generally by way of computer-aided sketch technology. This sort of manageability allows for a part to be engineered to an excessive degree of complexity such as relief and engraved elements. The accuracy is unmatched and requires minimal operator input.

Telemetry system are those which remotely monitor and distribute information over a distance. It has its origin in “tele” meaning remote and “metry” meaning measure. Telemetry systems are utilized in the largest systems which require external data gathering. Telemetry systems frequently relate to data transfer through wireless means but it also refers to information sent via other networks, such as telephones and computers. The growth in global communications and the rising calls are being utilized through telemetry information systems.